Get the latest tech news

MIT engineers develop a fully 3D-printed electrospray engine

MIT researchers demonstrated the first fully 3D-printed, droplet-emitting electrospray engine. The low-cost device can be fabricated more quickly than traditional thrusters, potentially from on board a spacecraft, and could enable CubeSats to perform precise, in-orbit maneuvers, aiding space research projects.

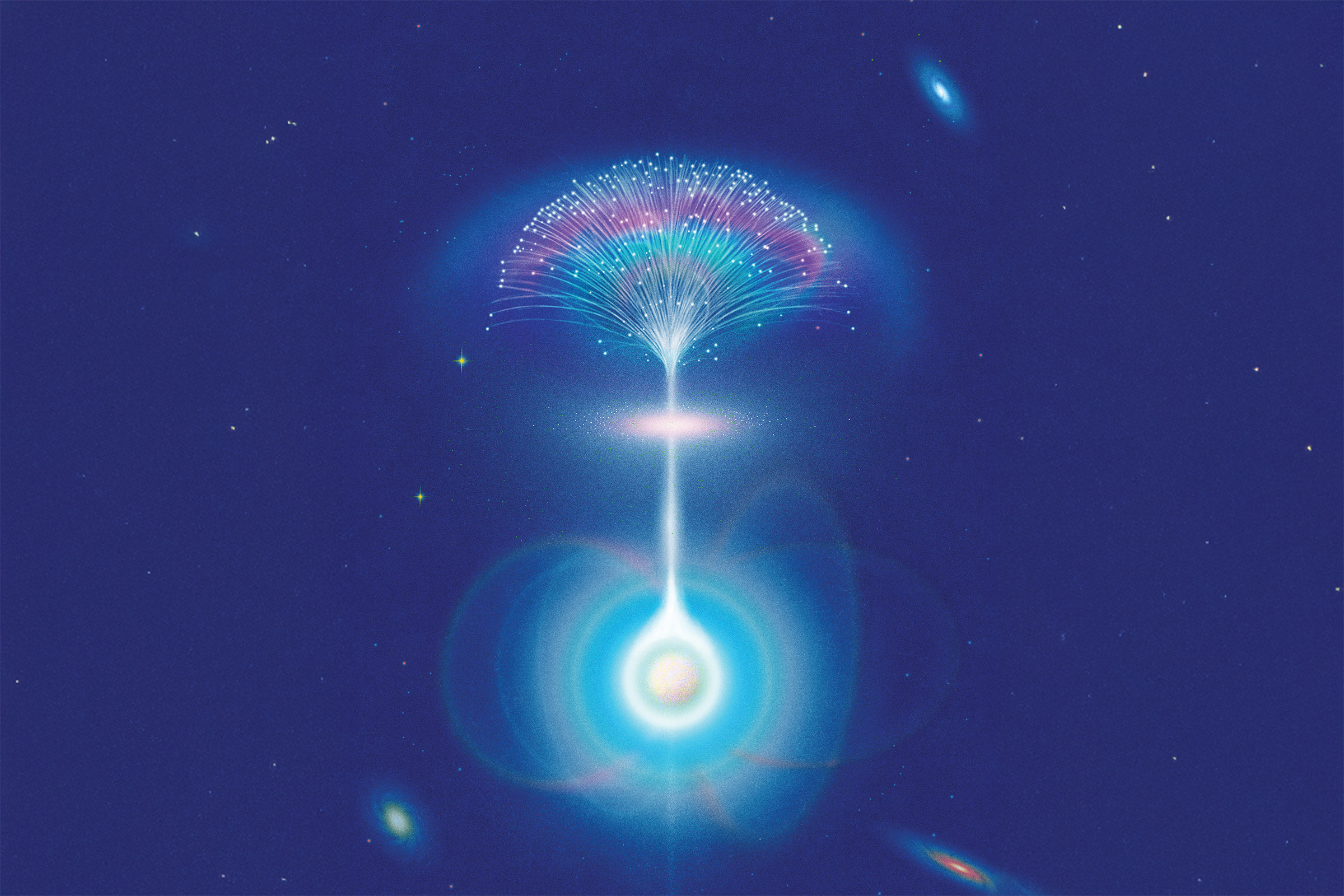

By developing a modular process that combines two 3D printing methods, the researchers overcame the challenges involved in fabricating a complex device comprised of macroscale and microscale components that must work together seamlessly. In this work, we are proposing a way to make high-performance hardware with manufacturing techniques that are available to more players,” says Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the thrusters, which appears in Advanced Science. An electrostatic field is applied at the tip of each emitter, triggering an electrohydrodynamic effect that shapes the free surface of the liquid into a cone-shaped meniscus that ejects a stream of high-speed charged droplets from its apex, producing thrust.

Or read this on r/tech